Our global impact

PRECISION IN ACTION:

OUR GALLERY OF EXCELLENCE

Step into the world of precision engineering with United CNC Machining’s Gallery of Excellence.

Here, we showcase the intricate, high-quality components that exemplify our commitment to unparalleled craftsmanship and innovation. United CNC Machining is known for our ability to rapidly produce even the most complex components on just about any material. Below are representative samples of the variety of CNC machined parts we can create.

United CNC Types of Machining:

- CNC Prototype Machining

- Billet Machining/CNC Machining

- 5-Axis Machining

- 4-Axis Machining

- 3-Axis + 2-Axis Machining

- 3-Axis Machining

- Surface Grinding

- CNC Turning & CNC Milling

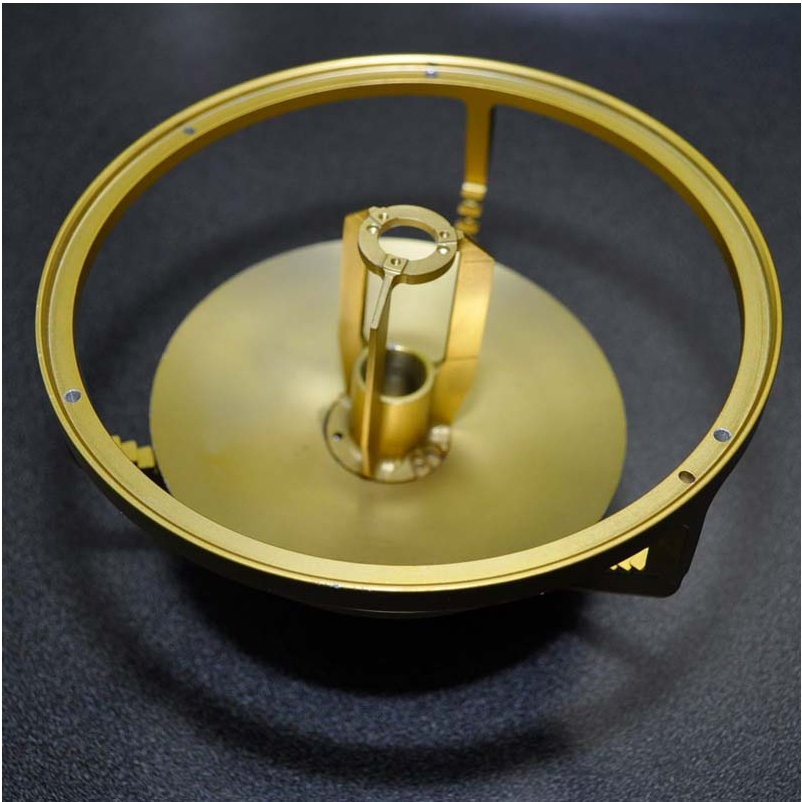

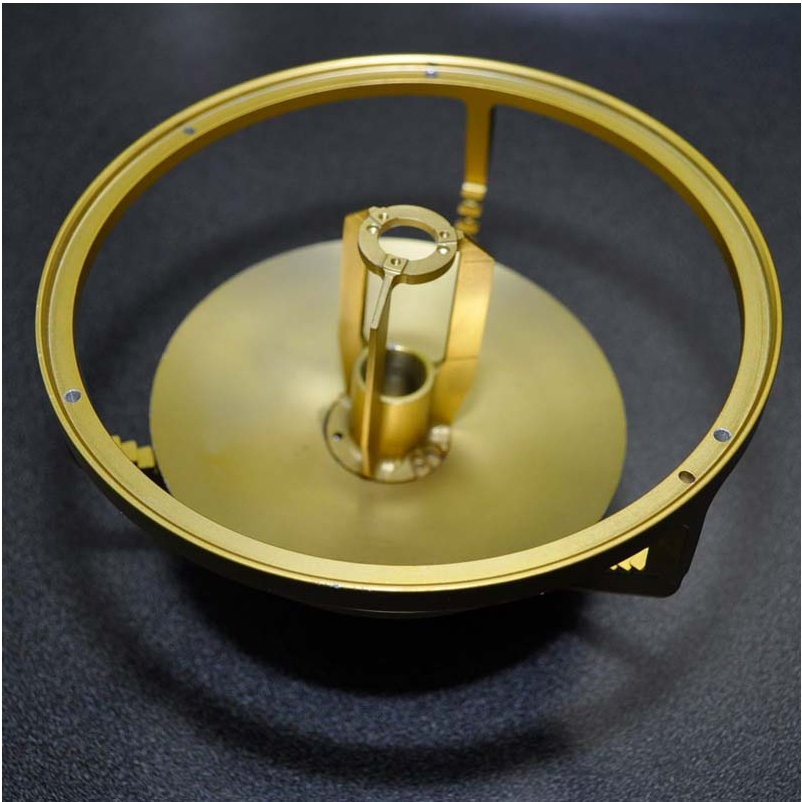

This precision-engineered brass mounting assembly highlights our expertise in multi-axis CNC machining, tight-tolerance manufacturing, and working with specialized alloys. Designed for critical automotive applications, this intricate part showcases exceptional craftsmanship with its circular frame, integrated mounting points, and flawless gold-anodized finish. Our ability to machine complex geometries and deliver durable, high-performance components ensures reliability and excellence for demanding industries.

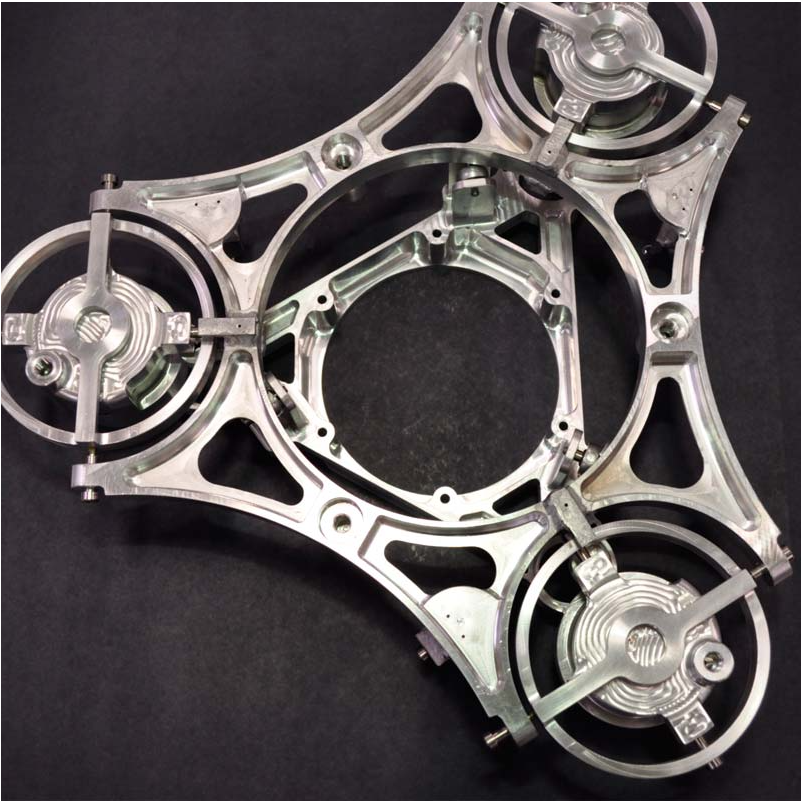

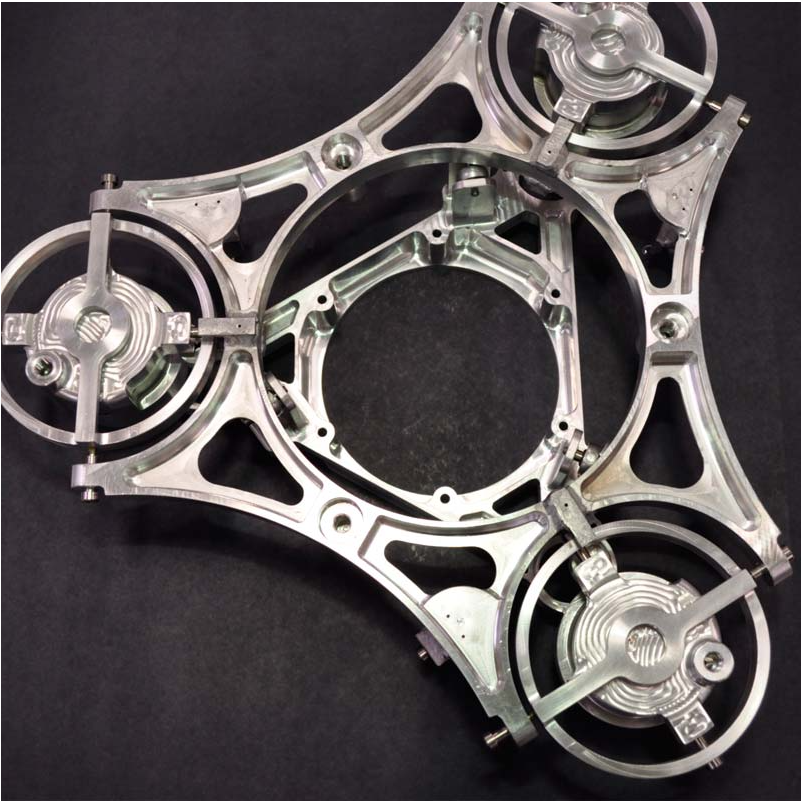

This intricate aluminum structure showcases our expertise in multi-axis CNC machining and lightweight design engineering. Manufactured from high-strength aluminum, this part features a complex webbed design with precise cutouts, integrated mounting points, and exceptional structural integrity. Its lightweight yet durable construction highlights our ability to meet the demanding requirements of the automotive industry, where strength-to-weight ratio and precision are critical. This component reflects our commitment to delivering innovative solutions for advanced mobility systems.

This black anodized cylindrical sleeve reflects our expertise in precision CNC machining and surface finishing technologies. Manufactured from high-strength aluminum, this part features a flawless anodized coating for enhanced durability, corrosion resistance, and performance in demanding defense applications. The intricate internal bore and external grooves showcase our ability to achieve tight tolerances and complex geometries, ensuring reliability in mission-critical systems. This component highlights our commitment to delivering advanced solutions for the defense industry’s most challenging requirements.

These precision-machined metal shafts showcase United CNC Machining’s capabilities in high-volume production, multi-axis CNC machining, and tight-tolerance engineering. Manufactured from durable stainless steel, these shafts are designed for powertrain systems in the automotive industry, ensuring reliability and performance under high-stress conditions. The consistent quality across the batch highlights United CNC’s ability to deliver scalable solutions for OEMs and Tier 1 suppliers.

This precision tool holder assembly demonstrates United CNC Machining’s expertise in tight-tolerance machining, multi-component assembly, and industrial-grade durability. The assembly includes a robust steel spindle and an intricately machined aluminum mounting bracket, showcasing their ability to produce components with perfect alignment and seamless integration. Designed for automation and industrial applications, this part highlights United CNC’s capability to deliver high-performance tooling solutions that ensure reliability and precision in demanding manufacturing environments.

This precision-machined pulley highlights United CNC Machining’s expertise in multi-axis CNC turning, tight-tolerance manufacturing, and surface finishing technologies. Crafted from high-strength steel, the part features a central bore, threaded mounting holes, and a meticulously machined outer groove for optimal performance in automotive powertrain systems. Designed to handle high rotational speeds and mechanical stress, this component showcases United CNC’s ability to deliver durable and reliable solutions for critical automotive applications.

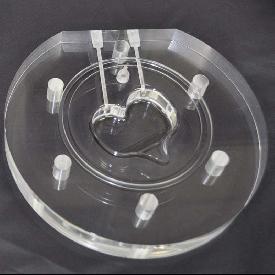

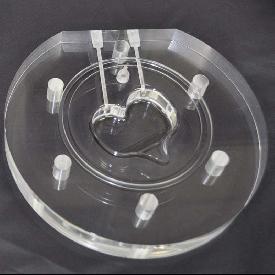

This custom acrylic fixture demonstrates United CNC Machining’s expertise in micro-machining, precision prototyping, and non-metallic material fabrication. Crafted from high-quality clear acrylic, this intricate component features a heart-shaped cutout, precise mounting posts, and polished edges, showcasing exceptional attention to detail and craftsmanship. Designed for advanced technology or commercial applications, this part highlights United CNC’s ability to deliver complex geometries and flawless finishes for delicate and visually critical projects.

This blue anodized drive pulley showcases United CNC Machining’s expertise in precision CNC turning, multi-axis machining, and anodized surface finishing. Manufactured from lightweight yet durable aluminum, this component features a central square drive and precision-machined grooves, ensuring optimal performance in aerospace applications. The anodized coating enhances corrosion resistance and durability, making it ideal for high-stress environments. This part highlights United CNC’s ability to deliver mission-critical components with tight tolerances and exceptional quality for the aerospace industry.

These precision knurled fasteners demonstrate United CNC Machining’s expertise in multi-axis CNC turning, tight-tolerance threading, and surface finishing. Manufactured from high-strength stainless steel, these components feature intricate knurling for enhanced grip, precision threading for secure assembly, and a polished finish for durability and aesthetic appeal. Designed for industrial and automation applications, these fasteners highlight United CNC’s ability to deliver high-performance components that ensure reliability in critical systems.

This gold-anodized housing showcases United CNC Machining's expertise in precision multi-axis machining, tight-tolerance manufacturing, and surface finishing technologies. Crafted from high-strength aluminum, this intricate component features internal cavities, mounting points, and a central bore, designed for critical aerospace applications. The gold anodized finish enhances corrosion resistance and durability, making it ideal for high-performance environments. This part highlights United CNC’s ability to manufacture complex geometries and deliver mission-critical components that meet the rigorous standards of the aerospace industry.

This precision-machined aluminum chassis highlights United CNC Machining’s expertise in large-scale CNC machining, tight-tolerance fabrication, and complex assembly integration. Designed for mission-critical defense applications, this robust component features intricate cutouts, threaded holes, and integrated mounting points, showcasing the ability to handle complex geometries and high-strength materials. The durable construction and flawless finish reflect United CNC’s commitment to delivering reliable, high-performance solutions for demanding environments.

This precision-engineered polymer guide demonstrates United CNC Machining’s expertise in multi-axis CNC machining, non-metallic material fabrication, and tight-tolerance manufacturing. Crafted from high-performance polymer, this intricate component features curved fins and precise contours, designed for advanced technology applications requiring lightweight, durable, and heat-resistant materials. Its complex geometry highlights United CNC’s ability to deliver innovative solutions for industries that demand precision and reliability in challenging environments.

This precision-engineered brass mounting assembly highlights our expertise in multi-axis CNC machining, tight-tolerance manufacturing, and working with specialized alloys. Designed for critical automotive applications, this intricate part showcases exceptional craftsmanship with its circular frame, integrated mounting points, and flawless gold-anodized finish. Our ability to machine complex geometries and deliver durable, high-performance components ensures reliability and excellence for demanding industries.

This intricate aluminum structure showcases our expertise in multi-axis CNC machining and lightweight design engineering. Manufactured from high-strength aluminum, this part features a complex webbed design with precise cutouts, integrated mounting points, and exceptional structural integrity. Its lightweight yet durable construction highlights our ability to meet the demanding requirements of the automotive industry, where strength-to-weight ratio and precision are critical. This component reflects our commitment to delivering innovative solutions for advanced mobility systems.

This black anodized cylindrical sleeve reflects our expertise in precision CNC machining and surface finishing technologies. Manufactured from high-strength aluminum, this part features a flawless anodized coating for enhanced durability, corrosion resistance, and performance in demanding defense applications. The intricate internal bore and external grooves showcase our ability to achieve tight tolerances and complex geometries, ensuring reliability in mission-critical systems. This component highlights our commitment to delivering advanced solutions for the defense industry’s most challenging requirements.

These precision-machined metal shafts showcase United CNC Machining’s capabilities in high-volume production, multi-axis CNC machining, and tight-tolerance engineering. Manufactured from durable stainless steel, these shafts are designed for powertrain systems in the automotive industry, ensuring reliability and performance under high-stress conditions. The consistent quality across the batch highlights United CNC’s ability to deliver scalable solutions for OEMs and Tier 1 suppliers.

This precision tool holder assembly demonstrates United CNC Machining’s expertise in tight-tolerance machining, multi-component assembly, and industrial-grade durability. The assembly includes a robust steel spindle and an intricately machined aluminum mounting bracket, showcasing their ability to produce components with perfect alignment and seamless integration. Designed for automation and industrial applications, this part highlights United CNC’s capability to deliver high-performance tooling solutions that ensure reliability and precision in demanding manufacturing environments.

This precision-machined pulley highlights United CNC Machining’s expertise in multi-axis CNC turning, tight-tolerance manufacturing, and surface finishing technologies. Crafted from high-strength steel, the part features a central bore, threaded mounting holes, and a meticulously machined outer groove for optimal performance in automotive powertrain systems. Designed to handle high rotational speeds and mechanical stress, this component showcases United CNC’s ability to deliver durable and reliable solutions for critical automotive applications.

This custom acrylic fixture demonstrates United CNC Machining’s expertise in micro-machining, precision prototyping, and non-metallic material fabrication. Crafted from high-quality clear acrylic, this intricate component features a heart-shaped cutout, precise mounting posts, and polished edges, showcasing exceptional attention to detail and craftsmanship. Designed for advanced technology or commercial applications, this part highlights United CNC’s ability to deliver complex geometries and flawless finishes for delicate and visually critical projects.

This blue anodized drive pulley showcases United CNC Machining’s expertise in precision CNC turning, multi-axis machining, and anodized surface finishing. Manufactured from lightweight yet durable aluminum, this component features a central square drive and precision-machined grooves, ensuring optimal performance in aerospace applications. The anodized coating enhances corrosion resistance and durability, making it ideal for high-stress environments. This part highlights United CNC’s ability to deliver mission-critical components with tight tolerances and exceptional quality for the aerospace industry.

These precision knurled fasteners demonstrate United CNC Machining’s expertise in multi-axis CNC turning, tight-tolerance threading, and surface finishing. Manufactured from high-strength stainless steel, these components feature intricate knurling for enhanced grip, precision threading for secure assembly, and a polished finish for durability and aesthetic appeal. Designed for industrial and automation applications, these fasteners highlight United CNC’s ability to deliver high-performance components that ensure reliability in critical systems.

This gold-anodized housing showcases United CNC Machining's expertise in precision multi-axis machining, tight-tolerance manufacturing, and surface finishing technologies. Crafted from high-strength aluminum, this intricate component features internal cavities, mounting points, and a central bore, designed for critical aerospace applications. The gold anodized finish enhances corrosion resistance and durability, making it ideal for high-performance environments. This part highlights United CNC’s ability to manufacture complex geometries and deliver mission-critical components that meet the rigorous standards of the aerospace industry.

This precision-machined aluminum chassis highlights United CNC Machining’s expertise in large-scale CNC machining, tight-tolerance fabrication, and complex assembly integration. Designed for mission-critical defense applications, this robust component features intricate cutouts, threaded holes, and integrated mounting points, showcasing the ability to handle complex geometries and high-strength materials. The durable construction and flawless finish reflect United CNC’s commitment to delivering reliable, high-performance solutions for demanding environments.

This precision-engineered polymer guide demonstrates United CNC Machining’s expertise in multi-axis CNC machining, non-metallic material fabrication, and tight-tolerance manufacturing. Crafted from high-performance polymer, this intricate component features curved fins and precise contours, designed for advanced technology applications requiring lightweight, durable, and heat-resistant materials. Its complex geometry highlights United CNC’s ability to deliver innovative solutions for industries that demand precision and reliability in challenging environments.